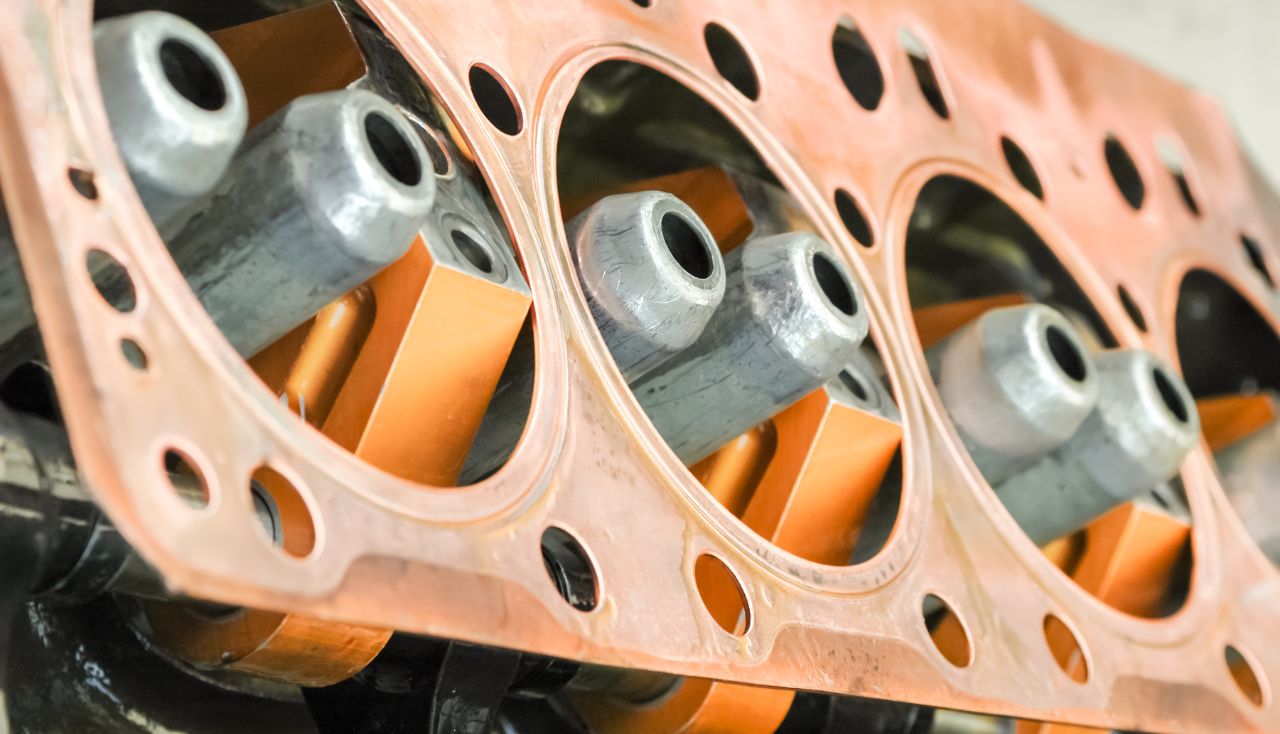

Photo by nelsonart On Envato Elements

The performance of the fuel injection pump is directly linked to the performance of the engine. In case your car is facing a problem with fuel delivery, it will eventually stop functioning. As a result, fuel injection problems are one of the primary concerns when it comes to engine maintenance.

It is beneficial to know about the fuel injector pump, its impact on engine performance, and the differences between diesel fuel injection pumps and traditional gasoline-powered ones, even if one has not encountered fuel injector failure before.

A Brief Overview of Diesel Fuel Injection Pumps

The function of a diesel fuel injection pump is to supply fuel to the internal combustion chamber of an engine. In high-performance vehicles, there is typically one fuel injector for each cylinder, and the pump delivers fuel to the combustion chamber, earning its name “fuel injector.”

The process of dispersing fuel from the injection pump to the combustion chamber is relatively straightforward. First, pressurized fuel is sent into the fuel injector. Then, the fuel is directed into a plunger through an electrically controlled solenoid valve, which functions as an on/off valve.

The plunger readies the fuel for its ultimate release. Finally, the fuel is distributed through a spray tip in the form of a fine mist.

Fuel Injection under Pressure

Nowadays, diesel fuel injection pumps are subjected to higher levels of pressure compared to the past. In the past, it was typical for fuel injector pumps to handle fuel at approximately 10,000 to 15,000 psi. However, modern engines are expected to operate at pressures twice as high. As we look at the current scenario, diesel fuel injector pumps are functioning within the range of 30,000 to 40,000 psi.

The effectiveness of an engine’s performance is largely determined by its ability to process fuel. In essence, a high-quality engine can process fuel and air more efficiently than a standard engine – this is why turbochargers are known for their ability to increase horsepower.

As a result, it is essential to have a higher internal pressure to achieve optimal performance. This is exemplified by the significant output pressure of modern fuel injection pumps, which far surpasses those used in the past.

The Dual Nature of the Culprit – Two Factors that Contribute to the Failure of Fuel Injector Pumps

Two main factors are responsible for 99% of diesel fuel injector malfunctions.

• Issues with the physical fuel injector housing caused by mechanical failures

• Poor fuel quality

A variety of issues may arise from these two factors. Now, we will examine four common fuel injector pump problems.

Issue #1 – Contaminated Fuel

A diesel fuel pump injector that is kept clean is a satisfied diesel fuel pump injector. As time passes, there is a possibility for the buildup of residue in the fuel system, which can cause blockage of the entire fuel injector pump due to excessive accumulation of grime and grease. The spray tip, which is responsible for releasing fuel from the injector into the combustion chamber, is especially vulnerable to getting clogged, so to speak.

If your engine has ever experienced sputtering or hesitation when accelerating, it could be due to a blocked fuel spray tip. This issue can be traced back to poor-quality diesel fuel. In 2006, adjustments were made to diesel fuel production to meet the standards for ultra-low sulfur diesel fuel (ULSD). As a result, owners of diesel engines have reported more challenges with “dirty fuel” than in previous years.

Issue #2 – Insufficient Fuel in Tank

If your ultimate objective was to damage diesel fuel pump injectors, you would operate your vehicle with the fuel tank as close to depletion as achievable. This is primarily due to the issue of lubrication. When there is an ample amount of diesel fuel in the tank, the fuel pump bearings receive an adequate amount of lubrication.

However, when the tank is almost empty, the fuel system is forced to push air instead of diesel fuel. This can result in the bearings of the fuel pump wearing out due to substances other than diesel fuel, thus causing the fuel injectors to not receive the required fuel at the designated pressure level (30,000 psi, 40,000 psi, etc.).

Issue #3 – Foreign Object Lodged in Injector

The diesel fuel pump injectors play a crucial role in the engine as they are highly precise components and are subject to a significant amount of movement and strain. The presence of even the tiniest of foreign objects such as dust or debris can result in the clogging of the injector. This can lead to further complications, as even a microscopic object can cause the injector to remain open, affecting the performance of the cylinder.

Issue #4 – Incorrect Injector Timing

If the O-rings or ball seats of the fuel injector pump are faulty, it can disrupt the timing of the fuel transfer process. This is a typical issue with diesel fuel injector pumps and often necessitates a full rebuild or replacement of the injection pump.

Reminder for Maintenance

The positive aspect of fuel injector pump issues is that it is easy to prevent disaster. By following these three steps, you can ensure optimal performance and keep repair expenses to a minimum:

*Buy dependable and pure fuel.

*It is recommended to replace your fuel filter every 40,000 miles.

*It is advisable to maintain your fuel tank at a minimum of one-quarter full for the majority of the time.